Until 2014 or so, the liquid by-product from cooking chickpeas was a waste product like any other. But then a French chef discovered that the humble liquid had amazing properties that helped it act like eggs when whipped. Aquafaba, as it came to be known, turned into an internet sensation among vegan foodies, and now, less than two years later, it has a Facebook group and a cookbook dedicated to it, and even a commercial product made from it. That’s the story behind Fabanaise, a new egg-free mayo from New York-based condiment maker Sir Kensington’s. What was once waste is now a resource in the commercial supply chain. We talked with the business’s co-founder and CMO Scott Norton about the challenges and rewards of pioneering a new supply chain from another company’s leftovers.

Sir Kensington’s At A Glance

Location: New York, NY

Founded: 2010

Employees: 33

Impact: Over 100,000 pounds of aquafaba diverted and upcycled in 2016

InterviewDoes Sir Kensington’s have a mission?

Scott Norton: Our mission is to bring integrity and charm to ordinary and overlooked foods. Every word in that statement has meaning. By “integrity,” we mean the way our ingredients are sourced. As any chef will tell you, you can’t make great food without great ingredients. That’s absolutely true for what shows up in grocery stores, too. Big food companies don’t necessarily think like that; they’ve spent the last 70 years trying to reduce the costs and, ultimately, reduce the quality of the products they’re selling in order to maintain a certain profitability margin. Luckily, American food is changing for the better right now. There’s an opportunity to bring integrity to it, and a market and an audience that’s really excited about that.

When we talk about “charm,” we mean that food is nourishment, yes, but it’s also entertainment. The charm that we bring is the flavor, the sensory experience, and the fun and the whimsy that come with our brand — the fact that our boss is a cartoon character.

“Ordinary and overlooked foods” are ones that haven’t yet changed or that haven’t had any inspiration breathed into them, ones that have gone forgotten over time. Our flagship products like ketchup, mustard, and mayonnaise are part of that overlooked group of food.

What about sustainability? Is that explicit in what you do?

SN: I wouldn’t say it’s so much explicit as it is implicit. We are, first and foremost, makers of food. We certainly have a value of stewardship and an understanding that we exist in an environment that, if we don’t treat it well, won’t be around anymore. We really try to think long-term as a company.

From an intentionality standpoint, our focus on sustainability is more on thinking about how food is so crucial to human health and nutrition and how it can be medicine or poison. Our products mainly provide flavor, but we believe that anything we can do to bring attention and excitement to real food and allow people to have intimate experiences with nature through food is something we’re proud of.

How did you first get the idea to use aquafaba in a Sir Kensington’s product?

SN: Our innovation started with the question, “Can we deliver classic mayo flavor without the use of eggs?” After trying a bunch of recipes, two of our summer interns in 2015 came across an article by Food52 about this new ingredient aquafaba that was being used to make meringues and icing. We wondered, “Could we use this as an emulsifier to create mayonnaise?” That was the first spark that compelled us to go into the kitchen.

After many, many trials and a lot of work, we were able to get the texture perfect. In order to add the savory flavor that egg yolks carry and aquafaba does not, we ended up adding kombu seaweed to create something that was wholly up to our standards. Though, of course creating a benchtop sample is different from creating a commercial recipe for grocery stores. That really began our quest to learn about how we could discover and generate a supply chain for aquafaba.

What was the first challenge you faced in getting this supply chain set up?

SN: The first challenge was knowing who we could even talk to. We knew that aquafaba was being poured down the drain by different companies, specifically hummus makers, but we didn’t know where they were, we didn’t know who they were. And there are many ways to make hummus, some of which create aquafaba and some of which don’t.

We went to Elly Truesdell, who is the local forager for Whole Foods in the Northeast, our home region, and she put us in touch with Chris Kirby, the founder of Ithaca Hummus. His company was young, nimble, on board with what we were trying to do, and also really liked the concept of upcycling waste products. They were keen on the concept and game for the idea. When you hear that something you’re pouring down the drain could not only be used to make real food but you also have the potential to sell it and make revenue from it, it’s a win-win.

From there, we were able to work in partnership with him to understand the food safety issues, the education issues, the ingredient issues, the logistical issues — all the things that need to come into play to actually secure the supply chain.

You found a partner. What happened next? What did you need to do from there?

SN: First, when you think about any supply chain, in food or in other categories, you need to consider three big things: dependability, scalability, and consistency. A traditional product will be manufactured to a spec . Waste products that come out of that process aren’t being managed to spec. When a waste output is becoming an ingredient — an input — it absolutely has to be up to spec. Likewise, it’s got to be scalable over time. Before, if all you were doing was creating hummus or creating one final product, maybe you weren’t focusing so much on your output of the waste. Now it’s much more of a balance. There has to be a plan in the future for the growth of this ingredient. You’re looking at selling multiple products, and thinking of these by-products as an input, so that has to be scaled and managed.

A second area, and this is incredibly important in food, is safety: good manufacturing practices and hygiene all the way from start to finish. We worked with Chris to design a system, looking at FDA guidelines and everything like that, to make sure that, even though this was a waste product, it was never treated as something that could be contaminated. That’s a conceptual shift, but it’s also very matter-of-factly a physical shift in how the ingredients are treated.

A third element is knowing how to tell the story. You have to be sure that people aren’t going to be grossed out that a waste product is going into food. That’s where words like “upcycling” come in, which can be universally lauded as a good thing. You have to understand, from a communications standpoint, who is your audience, and what is the best way to convey this message so that it’s received in a positive light that’s inspiring and that builds people’s curiosity? Also, very importantly, the message needs to be in line with what the hummus brand is all about and what the Sir Kensington’s brand is about.

In our case, what could be more ordinary and overlooked than the water from a can of chickpeas that gets poured down the drain? Making sure that you have a really considered way of sharing the story is the final element of that supply chain.

Fabanaise is the first commercial product to use aquafaba, the waste liquid from cooking chickpeas.

Has this new product using the aquafaba evolved how you think about sustainability in your business?

SN: Definitely. Creating great products that are enjoyed by the market, that’s downstream innovation. What this allowed us to do was think about upstream innovation. For the first time, we’re now looking at our company as having the potential to rescue more waste ingredients, to build supply chains from scratch, and to do more of that upstream innovation. What I don’t want to do is overpromise and under-deliver. I can’t say that we’re going to become a company overnight that is repurposing waste ingredients. But now it’s one more color in our palette.

Do you have any other specific lessons that you’ve taken away from closing this leak in the cosmic supply chain? Any other advice for someone who either is setting out to do this or, like you guys, discovers that there’s an opportunity for it?

SN: In supply chains in particular, tenacity is key. There’s no catalogue that you can page through to find useful waste products. You’re going to have to be flipping stones looking for these little gems. With the first couple of stones you flip over, you’re not going to find what you want. It really requires the inner geek and also the inner socialite to get to know people who are doing interesting things, to learn about their process, and to just keep experimenting.

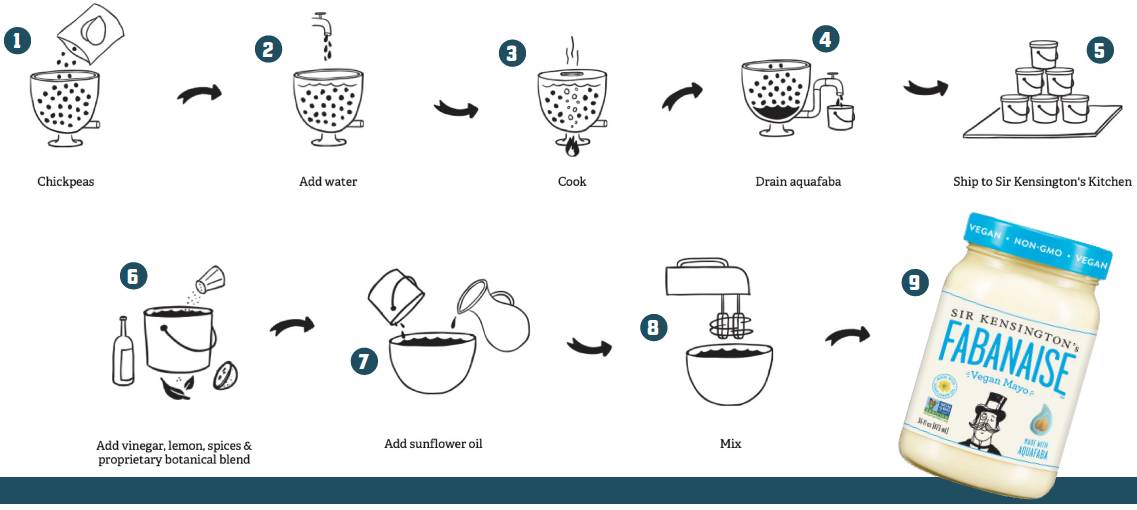

THE UPCYCLING CYCLE

How Fabanaise is made.

Where the aquafaba comes from

See what happens at Ithaca Hummus to create the aquafaba Sir Kensington’s uses in its Fabanaise product.

Step 1: Raw chickpeas!

Step 2: Cooking!

Step 3: Straining off the aquafaba (chickpea cooking liquid)

Step 4: Pouring the aquafaba into buckets for transport to Sir Kensington’s.

Tada! Products!